Exilva: A new sustainable natural texturiser

Abstract

Exilva, the new natural raw material sustainably produced from Cellulose , is ideally suited to improving the stability, the rheological behaviour and the sensoric properties of cosmetic products.

The various strengths of the cellulose-based material are displayed in different ways:

In the area of skin care, a strong matting effect can be achieved in products such as face creams, BB creams and decorative cosmetics by using Exilva.

Hair care formulas which contain Exilva as a raw material stand out thanks to a significant reduction in the combing forces.

Furthermore, in the field of sun care products, the extreme shear thinning and rapid viscosity recovery of Exilva makes it possible to develope formulations suitable for spraying.

Exilva can therefore sustainably enhance the raw material portfolio in different categories.

Origin of Exilva

Exilva, a Microfibrillated Cellulose suspension, consist of Cellulose in water. This new raw material comes from sustainable forests and will therefore be available in the future in almost unlimited quantities.

Raw material

In nature, cellulose is found as β-1,4-linked glucopyranose units. The polymer chains are linked via hydrogen bonds forming fibril bundles of both highly ordered crystalline regions and disordered amorphous regions in the plant cell wall [1].

Cellulose fibrils are responsible for the extremely high tensile strengths in the cell wall of plant fibres. These fibrils or fibril bundles are obtained from wood and other lignocellulosic fibre materials [2].

The fibril bundles are themselves linked to each other forming what we refer to as fibers.

When the cellulose fibers are treated with high shear forces, they are torn apart in a longitudinal direction to result in the thinner and higher aspect ratio microfibrils (higher surface area material) referred to as Microfibrillated Cellulose (MFC). These Microfibrillated Cellulose then form a 3D network in water. In order to obtain MFC’s from wood for example, high shear forces are used to disintegrate the cellulose fibers into finer structures.

The resulting 3D network is able to bind very high volumes of water. Exilva is Borregaard’s Microfibrillated Cellulose suspension. If dried, the 3D network structure of MFC and hence Exilva collapses losing its water-binding properties. The unique properties of the 3D network give Exilva a wide range of possible uses in water bond systems, polar solvents as well as a mixture of those.

By adding Exilva, it is possible to vastly improve the performance of many cosmetic products with regard to stability, rheological behaviour and their sensoric properties. This microfibrillated cellulose can also be used with great success when stabilising and opacifying cosmetics, and also as an adsorbent. In addition to these many attractive properties, Exilva is highly hydrophilic and available as a 2% suspension or a 10% paste raw material.

Production

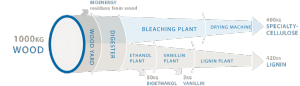

The diagram below schematically describes the production process of natural products of Borregaard.

Borregaard has developed the proprietary production process by themselves, a process which is vital to achieving the high performance of Exilva. The process enables the cellulose fiber to be split into smaller fibrills, creating the threedimensional network.

Applications

Exilva is ideally suited for modifying the rheological properties [3] of cosmetic preparations. Even small amounts enable a significant increase in viscosity of the respective formulation. The network that is formed after the microfibrillated cellulose has been incorporated also contributes to an improvement of the dispersion and stabilisation of particles in manufactured products.

This cellulose based raw material is further distinguished by the opacifying effect of the undissolved cellulose particles that are suspended in the matrix. In the skin care products industry for example, when using Exilva in face creams, BB creams or decorative cosmetics, this produces a very good mattifying effect and therefore a concealing and masking effect for small wrinkles on the skin.

The performance of hair care formulations can also be improved due to specific properties imparted on the formulations by Exilva. Combing wet hair can be made considerably easier by adding microfibrillated cellulose when rinsing.

An increase in the sun-protection factor in sunscreen formulations by using Exilva could unfortunately not be detected. However, the viscosity of sunscreen products after being sprayed onto vertical surfaces was significantly improved allowing a non-dripping effect.

Many formulations containing Exilva as a stabilising and/or rheology modifying agent are developed based on the distinct shear thinning effect imparted by the raw material in the formulation as well as its capacity for very rapid recovery of the original structure and therefore viscosity, all properties required for sprayable cosmetic applications.

The benefits and improvements from using Exilva are discussed in more details below, showing analysed data and observed properties in individual examples and specific formulations.

Skin care

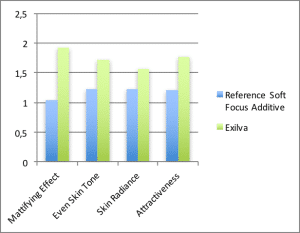

The mattifying effect of microfibrillated cellulose was tested in a face cream. The mattifying effect is due to the microsized irregularly shaped flexible aggregate and can help conceal wrinkles in the skin when used in cosmetic preparations.

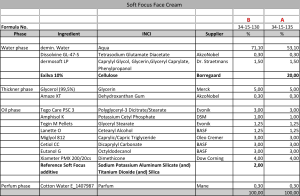

To determine the mattifying effect of Exilva, matt face creams with different compositions were first produced in accordance with the formulations described in Tab.2.

The mattifying effect of individual creams was established in a ‘soft focus test’ on test subjects. A photograph of the face was taken beforehand. An appropriate amount of cream was then applied to the face and after waiting

ten minutes, another photo of the face treated with the cream was taken. Next, trained raters were each presented with a treated and untreated half of the face for assessment. The photos were shown to the raters on a calibrated screen, without stating which half of the face was treated and which was untreated. The absorption times were not shared with the raters either. At the end of the study, six raters rated the test subjects according to criteria of ‘mattifying effect’, ‘even skin colour’, ‘radiant skin’ and ‘attractiveness’ [4].

According to the assessment data, the skin creams produced with Exilva scored higher in terms of performance than Sodium Potassium Aluminum Silicate, CI 77891 (Titanium Dioxide), Silica used as a benchmark in all comparisons. In the ‘mattifying effect’, the ‘even skin colour’ and ‘attractiveness’ categories a significant effect was noted using Exilva.(Fig.2)

Fig3. Pictures after product application

After using product A (2% Exilva), this test subject’s (Fig.3) skin was considerably less shiny and had a more even appearance.

Hair care

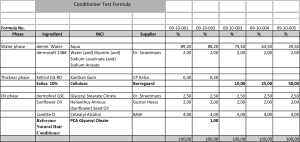

Combing can be significantly improved by using conditioners, particularly when combing wet hair. Exilva provides developers with a silicone-free raw material produced from sustainable primary products which demonstrates these properties in rinsing.

A basic formula with different additives in varying quantities was prepared for the relevant experiments. The individual formulations are listed in Tab.3.

Testing was carried out after washing and rinsing hair under defined conditions by measuring the forces which occur when combing pre-treated hair. Ideally, the substances added to the rinsing produce a film on the hair and reduce the force needed to comb through the hair.

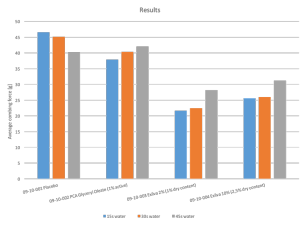

When testing the conditioners both blonde and grey hair were used. While the results for blonde hair were comparable to the use of the benchmark product PCA Glyceryl Oleate, on grey hair the rinses carried out using Exilva were clear winners in the combing experiments: A significant reduction of the combing forces was achieved after applying different concentrations of microfibrillated cellulose.

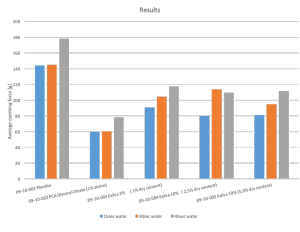

The results of the experiments are summarised in the graphs below:

Graph showing measurement of combing force on blonde hair

Graph showing measurement of combing force on grey hair

Sun care

The method of increasing the sun protection factor of sunscreen formulations by using Exilva (SPF boosting effect) was implemented with an SPF of 25 in comparison to known SPF booster Trimethoxybenzylidene Pentanedione. A known SPF booster, in accordance with ISO 24444 (November 2010), was added to the sunscreen produced for this purpose.

Unfortunately, in the in-vivo tests, the SPF boosters used did not demonstrate the significant improvement anticipated.

However, two positive effects were found during these experiments for the formulations which incorporated Exilva:

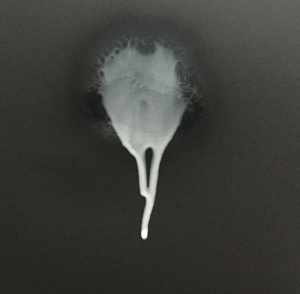

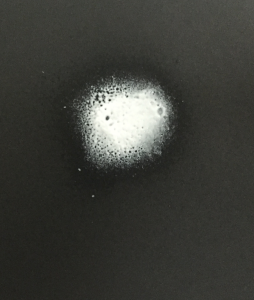

Firstly, the samples made with the microfibrillated cellulose displayed very rapid viscosity recovery when the sunscreen formulation was sprayed, which was greatly reduced during the spraying procedure when shearing.

This is demonstrated below by the images taken of the sunscreen spray experiments, with and without Exilva.

Formula without Exilva

Formula with 1% Exilva

Secondly, the sensoric properties of products normally perceived as oily and too rich was considerably changed by using microfibrillated cellulose and they became more velvety. A clear product advantage brought about by the addition of Exilva.

Summary

In summary, it can be established that many product properties, such as rheological behaviour, the mattifying effect and combability can be significantly improved in several formulations by using Exilva the microfibrillated cellulose.

In this case, further advantages in terms of the incorporation, stability and performance of the formulated products can be gained through the properties brought into the formula by the microfibrillated cellulose.

Exilva is therefore a very valuable, sustainably-produced raw material which is ideally suited to the continual enhancement of the raw material portfolio of different product categories.

Contact for questions and samples:

*Rebecca Blell, PhD, Research Scientist

Borregaard AS

Hjalmar Wessel Vei 10

1721 Sarpsborg, Norway

Email: Rebecca.Blell@borregaard.com

*Reinert Fure, PhD

Borregaard AS

Hjalmar Wessel Vei 10

1721 Sarpsborg, Norway

Email: Reinert.Fure@borregaard.com

**Rainer Kroepke, Director

Cosmacon GmbH

Kiebitzweg 2

22869 Schenefeld, Germany

Email: rk@cosmacon.de

References

- [1] R. M. Brown, and I. M. Saxena, Plant Physiol. 38(1/2), 57–67, (2000)

- [2] Dieter Klemm, Brigitte Heublein, Hans-Peter Fink and Andreas Bohn Angew. Chem. 2005, 117, 3422 – 3458, Cellulose: faszinierendes Biopolymer und nachhaltiger Rohstoff [Cellulose: fascinating biopolymer and sustainable raw material]

- [3] A. Karppinen, T. Saarinen, J. Salmela, A. Laukkanen, M. Nuopponen, and J. Seppälä,Cellulose 1–13, (2012)

- [4] Nathalie Lunau, Stephan Bielfeldt, Matthias Seise, Klaus-P. Wilhelm; New method to assess soft focus parameters on living skin: How does it compare to visual lay person rating of skin radiance? proDERM Institute for Applied Dermatological Research; 2015; Interne Methodenbeschreibung [internal description of methods]