Liposomes

Liposomes (Greek liposoma = fatty body) were first produced in a controlled and reproducible manner by Bangham in 1961 to investigate the structure and function of biomembranes. The term “liposome”, which is still used today, was coined by Sessa and Weissmann. US patent 3957971 was filed in 1974 and granted in 1976. It was the starting point for the development of liposomes as a new dosage form and active principle for skin care products.

However, it was not until 1986 that the first liposomal cosmetic was introduced, and since then it has been more or less successful in waves.

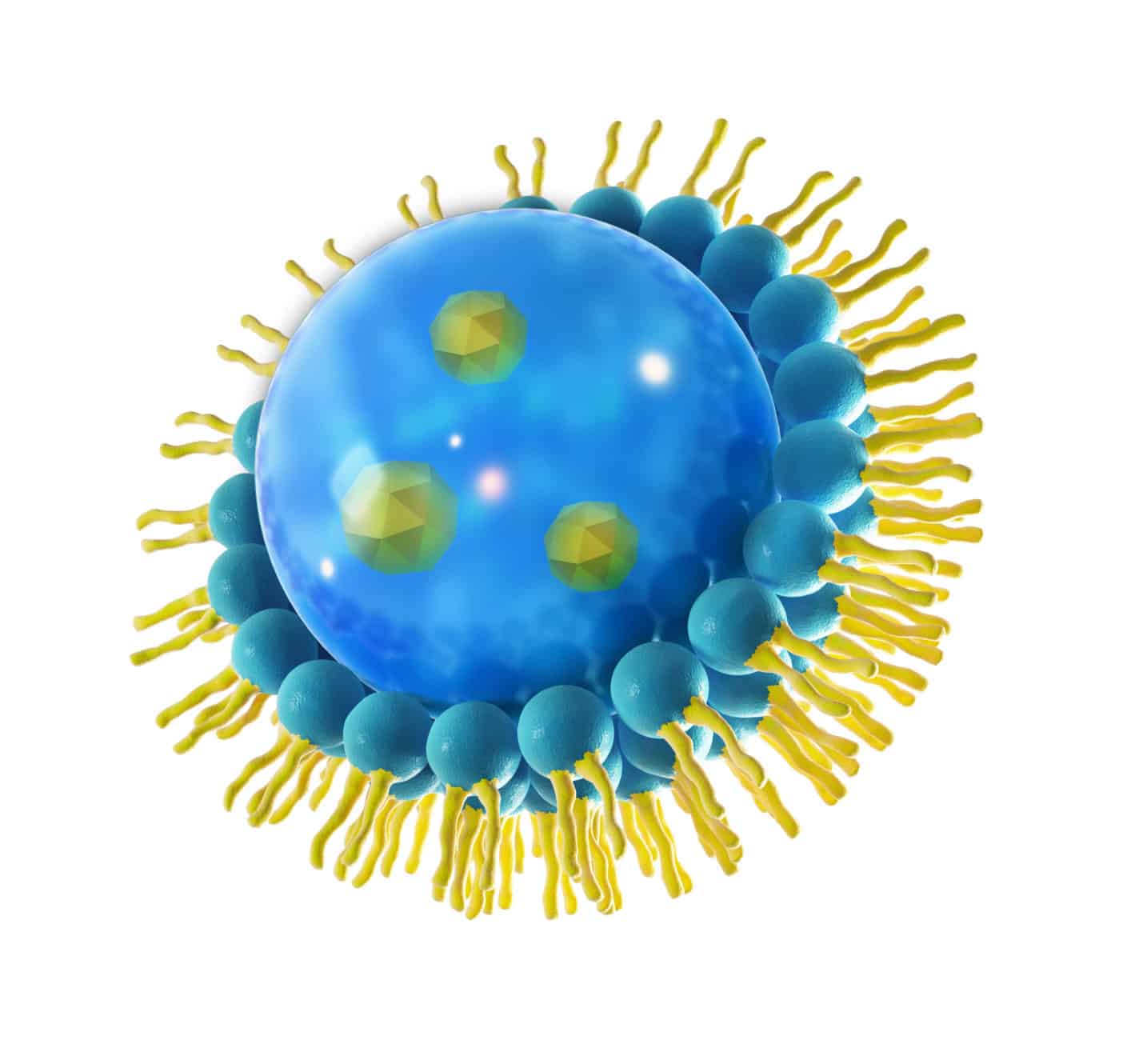

By definition, liposomes are single or multi-layered hollow spheres consisting of amphiphilic phospholipids whose lipids are fatty acid chains in one or more lipid bilayers (lamellae) together.

The hydrophilic parts are directed towards the outer aqueous phase and the interior of the hollow sphere and ensure water solubility. Due to their structure, liposomes can absorb lipophilic, hydrophilic and amphiphilic substances. The size of liposomes can vary from 25 to 10,000 nm.

Their size, distribution and lamellarity essentially depends on the manufacturing process used.

The phospholipids can be of natural, semi-synthetic and synthetic origin, with the focus being on plant-based phospholipids:

- Phosphatidylcholine (PC, charge-neutral),

- Phosphatidylethanolamine (PE, charge-neutral),

- Phosphatidylinositol (PI, negative),

- Phosphatidylserine (PS negative),

- Phosphatidic acid (PA, negative).

Depending on their fatty acid composition, the phospholipids can be unsaturated, partially hydrogenated or hydrogenated. The main component is usually phosphatidylcholine.

Esterified phosphatidylcholines with oleic or linoleic acid are lecithins, which is difficult to recognise from the INCI declaration because the liposomes are usually declared as “lecithin”.

Sphingosomes

The coating material of sphingosomes consists of sphingolipids, which are not derived from glycerol like phospholipids, but from sphingosine, a C18 amino alcohol or sphingosine derivatives (e.g., phytosphingosine). Whilst sphingosine is a characteristic component of mammalian lipids, phytosphingosine forms the basic framework for plant sphingolipids. The second building block, the fatty acids, are bound via the amino group as

amides via the amino group. These simple sphingolipids are known as ceramides.

Sphingosomes are frequently used in skin care products for sebostatic and seborrhoeic skin conditions.

Niosomes

The term “niosomes” is patent-protected and describes synthetic non-ionic surfactants. They are also known as non-ionogenic surfactant vesicles.

Niosomes can consist of

- Polyoxyethylene alkyl ether,

- Polyoxyethylene alkyl ester,

- Glycosyl dialkyl ether,

- Carboxylic acid diester of sucrose or

- Polyglycerol alkyl ether

The latter are linear or branched and prove to be inert to hydrolytic influences. Ethers are more stable than the esters, but have a higher irritation potential on the skin. The sucrose diesters form vesicles with an average particle size of 290-1080 nm, depending on the chain length of the carboxylic acid. Niosomes can supply the stratum corneum with water, prevent dry skin and ensure the transport of various substances into the horny layer. They are practically another type of liposome and perform the same function as a cosmetic.

Nanoparticles

These nanoparticles, also known as nanosomes, nanoparts and nanospheres, have a shell of sphingolipids, phospholipids or ceramides. In a sense, they represent the reverse of liposomes, as they spontaneously form a water-soluble membrane and enclose a lipophilic content

The loading capacity with oils and oil-soluble substances, such as vitamins A, D, E, K, evening primrose or wheat germ oil, is around 30 times higher than that of liposome membranes. Nanoparticles represent another effective concept in cosmetics and penetrate deep into the skin.

Conclusion:

Encapsulation systems in cosmetics are specialised technologies in which active ingredients are encapsulated in tiny capsules to increase their stability and enable targeted release. These systems offer a number of advantages:

- Stability of active ingredients: Encapsulation protects sensitive active ingredients from external influences such as light, oxygen or chemical reactions. This increases their stability and shelf life in the formulation.

- Targeted release: The capsules can be designed so that they only release the active ingredient when certain conditions are met, for example when applied to the skin or in contact with moisture. This can improve the effectiveness of the active ingredient and achieve a more targeted effect.

- Improved penetration: Encapsulated active ingredients can be released into deeper layers of the skin as the capsules help the active ingredients to develop their effect in the desired area.

- Long-term effect: Some encapsulation systems enable a long-lasting release of the active ingredient over a longer period of time. This can be particularly beneficial for moisturising or nourishing products.

- Reduction of irritation: For active ingredients that can cause skin irritation, encapsulation can delay or attenuate the release.

- Improved formulation compatibility: Some ingredients may not mix well in conventional formulations. Encapsulation systems can help overcome this incompatibility by keeping the active ingredients separate until they are released.

- Examples of encapsulation technologies in cosmetics include liposomes, nanoparticles, microcapsules and polymers, which can be used depending on the application and desired effect. These systems make it possible to improve the performance and effectiveness of cosmetic products by increasing the stability of the active ingredients and making their effect more targeted and efficient.

Cosmacon is happy to use such systems for your cosmetic products in order to increase the effectiveness or minimise the irritation of high-dose active ingredients. Please do not hesitate to contact us.

Sources

Brunke, R.A.; Charlet, E. Produktion und Nachweis von Liposomen, Sphingosomen und Nanopartikeln; SÖFW (117) 14: 514 – 517, 1991

Papahadjopoulos, D. ;Liposomes and their uses in biology and medicine. Ann NY Acad Sci, 308: 1-462, 1978

Billek, D.E. Phospholipids in personal care preparations. SÖFW (110) 117: 621 – 623, 1991

Gareiß, J.; Hoff, E.; Ghyczy, M.; Phospholipide – Liposomen – Nanoemulsionen. Parfum Kosmet 10: 652 – 659, 1994

Theis, H.; Göhring S.; Einsatz von Sphingolipiden in Hautpflegeprodukten. SÖFW (121) 5: 342 – 348,1995

Engst, R.; Liposomen – ein neues Therapiekonzept in der Dermatologie? Dt Dermatologe 8: 1171 – 1177, 1992

Soehnlein, H.S.; Brunke, R.A. Die neue Liposomen-Generation. SÖFW (115) 3: 85 – 87, 1989

Sabine Guett; Rheologische in vivo-Untersuchung an der menschlichen Haut mit nicht-invasiven Verfahren, Dissertation, 1998

Handjani-Vila, R.M.; Ribier, A.; Roudot, B. Dispersions of lamellar phases of non-ionic lipids in cosmetic products. Int J Cosmet Sci 1: 303 – 314, 1979

Kiwada, H.; Niimura, H.; Fujisaki, Y.; Yamada, S.; Kato, Y. Applikation of synthetic alkylglycoside vesicles as drug carriers. I. Preparation and physical properties. Chem Pharm Bull 33: 753 – 759, 1985

Ishigami, Y.; Machida, H. Vesicles from sucrose fatty acid esters. J Am Oil Chem Soc 66: 599 – 603, 1989

Baillie, A.J.; Florence, A.T.; Hume, L.R.; Muirhead, G.T.; Rogerson, A. The preparation and properties of niosomes – non-ionic surfactant vesicles. J Pharm Pharmacol 37: 863 – 868, 1985

Current Applications of Liposomes for the Delivery of Vitamins: A Systematic Review. Chaves MA, Ferreira LS, Baldino L, Pinho SC, Reverchon E.Nanomaterials (Basel). 2023 May 5;13(9):1557

Liposomes as Carriers of GHK-Cu Tripeptide for Cosmetic Application. Dymek M, Olechowska K, Hąc-Wydro K, Sikora E.Pharmaceutics. 2023 Oct 18;15(10):2485

Liposomal Bilayer as a Carrier of Rosa canina L. Seed Oil: Physicochemical Characterization, Stability, and Biological Potential. Jovanović AA, Ćujić D, Stojadinović B, Čutović N, Živković J, Šavikin K.Molecules. 2022 Dec 29;28(1):276